Team 1 (Sam, Cole, Nik, and Pedro) went for an asymmetrical design, driven by two strong rubber wheels in the back. An arm with a claw lowered down on one side to scoop up the rocks, bringing them up and over to drop into a large hopper, with more than enough capacity for all four rocks.

|

| Team 1 presents their design to the class |

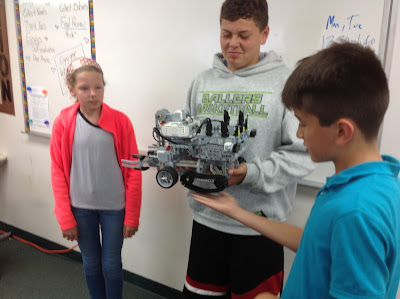

Team 3 (Conner, Brennan, Isaac, and Tessa) decided to maximize speed and agility above all else. They gave their robot a very simple platform on the front, with a swinging arm to contain a single rock at a time. This meant that they would have to exit and re-enter the circle each time to extract their rocks.

|

| Team 3 shows their simple but fast design |

Team 4 (David, Samy, and Belen) went for a longer model with more than enough internal capacity for four rocks. Completely unique to the competition, they designed a "paddle wheel" on the front to sweep the rocks right into the belly of the robot. This all made for more difficult turning, but an efficient collection method.

|

| Team 4 shows the longest design in the competition |

Lastly, Team 26 (Todd, Ashlynne, and Deacon) designed a big, bulky robot with both caterpillar tracks and rubber wheels. Team 26 was the only team to employ two computers onboard, to account for their large number of motors. A robot arm reached over the front of the robot to close onto the rocks, before lifting them up into the hopper behind.

|

| Team 26 shows the class their hybrid machine |

After a day of presenting and time trials, the students played it out in the gym, with parents and fellow students cheering on. Each team scored at least one victory against someone else, although by the end of the first day, it was clear that Team 3 had an obvious speed advantage. With each round of play, they perfected their technique to get faster and faster!

|

Mr. Meadth and the crowd look on as Team 26 positions for another run;

Team 4 paddles its way forward unhindered

|

|

Brennan and Conner from Team 3 close in on another rock; Todd and Deacon

from Team 26 try to co-ordinate their efforts

|

|

Samy from Team 4 takes a turn at the controls while David

and Belen look on

|

On the second day of competition, the students knew it was time for the eliminations. Team 26 and Team 4 had given the shakiest performances up to this point, although both had won a victory against each other. Fighting for the best of three saw a victory in 1:03 for Team 4, then a victory in 1:15 for Team 26. With scores tied, Team 4 pushed through in their fastest performance yet, with an astounding 0:54. Team 26 eliminated!

|

Samy, holding three, anxiously waits for the fourth rock to

be collected by David

|

|

Ashlynne, having positioned Team 26's robot, looks on as Deacon steers it

toward the goal

|

In the next elimination round, the bulkier Team 1 faced off against the more agile Team 3. In a quick series of best of three, Team 3 established dominance, putting their fastest time on the board of four rocks in 0:30. Team 1 put in a valiant effort, but could not keep up and was eliminated.

|

| Team 1 scoops up their second rock in the elimination round |

|

Conner from Team 3 positions the robot as Brennan gets ready to make a run for

the pink rock

|

The very long Team 4 and the very quick Team 3 went through to the final round, for another best of three. Tensions were high, and Team 4 started off strong. Team 3 went straight into their typical repertoire: run in, grab, get out, repeat. Like a well-oiled machine, Team 3 took home a victory in 0:50. In the second of three, Team 4 came close to victory, but Team 3 once again won with 1:12--notabley, not as fast as Team 4's best time. However, a third round showed that, without a doubt, Team 3 deserved the grand prize!

|

| Team 4 (left) and Team 3 fly into action in the final round |

|

Already holding two, Team 4 (left) narrowly misses their next red rock, while

Team 3 closes in on the teal one

|

The winning students were awarded with gift cards and one of the rocks they had fought so hard to collect. Smiles all round, and we'll see what the Final Challenge had to hold in store next year!

|

| Mr. Meadth congratulates Tessa, Conner, Brennan, and Isaac for a job well done |

|

| All the students with their robots at the end of the tournament |