(The fifth in our student blog series, written by Sam in 11th Grade, is followed by the teacher's two updates on the project, so please read all the way down! Flight tests were finally successful, as students and teacher alike learned the hard realities of "going back to the drawing board!")

While we don’t plan on taking him to the sun, Icarus was the name we selected for our massive hexacopter drone. With a 31-inch diameter, and the theoretical ability to lift almost two pounds on top of its own five-pound weight, it is operating at the higher end of recreational drone constraints. Most commercially available drones today feature only four propellers, and a mass of around one pound.

|

| Early sketches of the design, with design priorities listed on the side |

When we were designing “Thiccarus” we decided to push the boundaries with the materials we had available. A hexacopter design, as opposed to a more common quadcopter (a standard recreational design with four propellers), gave us more lift power and stability with a trade off on speed and maneuverability. To reduce weight and maintain strength Thiccarus would be constructed with 3D printed body parts and carbon fiber struts connecting them. However, when we were brainstorming, we decided that our drone’s primary function would be cargo delivery (despite my suggestions to make it into a fishing drone or a laser-toting drone with a search and destroy mission).

We came up with our design, then our constraints and requirements. After this, we split into design teams, each headed by ”captains.” After the protective shrouds around each propeller and control center base were decided upon, we set to starting a joint Onshape project. Onshape is our 3D design platform of choice for this project. Each team member was assigned one component of Thiccarus to design, and it came together well in a collaborative fashion. Each member of the design team is able to see in real time how their part will integrate with the other parts, which is incredibly helpful.

|

| The eight students work concurrently on the drone CAD model, with each one instantly able to see how their component fits into the broader scope |

|

| The hexacopter design emerges! |

|

| The largest and most difficult piece to print: the central electronics platform; five or six attempts at printing were required |

Icarus is currently in the printing stage, and when it is fully constructed, it will be mounted with two cameras feeding to a battery powered LCD screen. Steered by the controller, it will be capable of flying high and low to deliver small payloads.

(Sam's article was written in early October. After a delay in printing production due to some technical difficulties, the entire drone was finally fully assembled and taken for some early test flights. And now the update—which gets a little technical...)

After many hours of printing and assembly...

|

| Sam, Ben, and Todd carefully attach the motors and batteries and other electronic components |

The 8th Period engineering class proudly marched their huge drone out to the Providence soccer pitch. Gentle (and safe!) power-ups in the classroom had proved troublesome, with erratic behavior being immediately apparent. The drone was very touchy, and tended to spin around and roll to one side. Cutting the throttle from even six inches of altitude caused the aircraft to fall with a ungraceful "thump", with small 3D-printed pieces occasionally breaking off.

Alena gave an insightful suggestion that we could take it outside and stretch out a big sheet of fabric to catch the drone as it fell. This would allow us to try to gain more altitude—and more time to evaluate its behavior and get it under manual control. The soft fall into the fabric would certainly keep both drone and students completely safe! As an added bonus, we would look comically like cartoon fire-fighters.

|

| The group heads outside to try an initial flight: safety goggles on! |

And look like cartoon fire-fighters we did! The plan worked rather well, except for Ben slipping accidentally in a mud patch on the field in his zeal for saving the drone. With the extra flight altitude and time, we learned that the machine wanted to spin on its vertical axis—absolutely out of control. Where it should have lifted gingerly into the air and hovered obediently, it was a veritable whirling dervish, and the group could not even agree on their recollection of whether it had spun clockwise or counter-clockwise!

In a typical situation like this, the pilot should be able to add in some "yaw" trim. This means that the controller is set to always provide a little bit extra of yaw control, intended to counteract whatever is naturally happening and make everything balance out again. But adding yaw trim in either direction just didn't change anything, and after one particularly wild spin the drone fell outside of the fabric and broke one of its 3D-printed propeller shrouds.

|

| It may look like the class is flinging it into the air—we promise it is actually flying! |

In a typical situation like this, the pilot should be able to add in some "yaw" trim. This means that the controller is set to always provide a little bit extra of yaw control, intended to counteract whatever is naturally happening and make everything balance out again. But adding yaw trim in either direction just didn't change anything, and after one particularly wild spin the drone fell outside of the fabric and broke one of its 3D-printed propeller shrouds.

|

| See that tilt to one side? About three seconds later Thiccarus successfully escaped our circle of friendship! |

Back to the drawing board...

When all else fails, Google it. Apparently, when your drone experiences untrimmable yaw, it is likely the result of not having set all motors perfectly level. In other words, one or more propellers might not be perfectly flat relative to the ground, but tilted slightly to one side. And yes, this is quite noticeable on poor old Thiccarus once you look for it. Fortunately, it can be easily solved by readjusting the four screws that hold each motor down, and putting a little "shim" on one side to nudge it up to level.

This is actually an interesting application of standard high school trigonometry. If a thrust vector is pointing straight up to sky, well and good. This is what the flight controller is banking on for its power distribution calculations. But if a motor is tipped to one side by even two or three degrees (barely perceptible to the eye), the aircraft will experience a mysterious lateral force equal to the thrust times the sine of the angle. If the motor is generating a healthy 500 grams of thrust (a little over a pound), three degrees of tilt creates 26 grams of sideways thrust (500sin3°). Small but significant—and the flight controller is not accounting for it.

Maddening: yes. Fixable: absolutely. The motors will be checked and adjusted, and Thiccarus will be bandaged up and flown again. It is also very likely that a Mark II design will surface in the second semester, with higher tolerances for motor angles accounted for from the very beginning and a lighter airframe. Less airframe weight means longer flight times, a more responsive drone, and a greater possible payload.

Providence Engineering Academy: carry on!

As promised, the motors were checked and adjusted. Ben and Mr. Meadth stayed after school and carefully placed pieces of card under this or that side of the motors to shim them up, bringing them as close as possible to vertical. Three motors were in need of adjustment, but none of them were out of line by more than about two or three degrees.

The drone was powered up, with high hopes... but the end result was exactly the same. Thiccarus wanted to flip over to the side and rotate faster and faster, and nothing could persuade him otherwise. Forget flying too close to the sun—Thiccarus couldn't even get off the ground!

And then...

And then...

Mr. Meadth had his flash of inspiration, and it all came down to this image:

This diagram shows the initial wiring and setup instructions from the flight controller. A certain teacher thought he had carefully followed the diagram; unfortunately, he had set the actual propeller directions all opposite. For example, propeller 1 was supposed to be rotating clockwise, but it had been set up to be counter-clockwise.

What's the big deal, you ask? Well, while having everything opposite would still be balanced to some degree, the flight controller uses the spinning propellers to control its yaw. Say the craft wants to yaw to the left, it chooses a propeller to spin faster to the right (like propeller 1), and Newton's Law of Reactions takes over. If it wants to yaw to the right, it might choose a left-spinning propeller to do that (like propeller 2). But since each and every one was backwards, the corrective actions it tried to take were in every case making the situation worse. If it started drifting left, it would end up spinning more left—a classic vicious circle if ever there was one.

A quick click of a checkbox in the computer and that was solved. All propellers: backwards. Oops.

Today marks another successful series of flights. We currently get about ten minutes of air time with two fully charged batteries. Three students plus teacher have been brave enough to fly around a little bit. No major accidents—perhaps a leg snapping off here or there with a rough landing!

Lessons learned:

- It is possible that the flight controller—the 1-inch small box that houses gyroscopes and inputs and outputs and magnetometers and so on—is just misbehaving or badly calibrated. But after several recalibrations and trying an alternate one that we had in stock, there was no improvement. Check.

- Is Thiccarus just way too "thicc"? Maybe. We could have designed more aggressively, and perhaps brought him down to 2 kg even (4.4 lb). But the specs say that each motor should be able to create up to 550 grams of thrust. With six motors in total, that's 3.3 kg of thrust available (7.3 lb). And it's definitely getting off the ground, even with the thrust output turned down for safety. So: check.

- It is possible that one or more motors are just misbehaving or getting bad signals. Tiny, threadlike wires carry the commands between the different components, and we have run into problems of this nature before. But replacing one bad cable fixed that, and simple individual motor bench tests show snappy, responsive motors that will blow your papers away from across the room.

When all else fails, Google it. Apparently, when your drone experiences untrimmable yaw, it is likely the result of not having set all motors perfectly level. In other words, one or more propellers might not be perfectly flat relative to the ground, but tilted slightly to one side. And yes, this is quite noticeable on poor old Thiccarus once you look for it. Fortunately, it can be easily solved by readjusting the four screws that hold each motor down, and putting a little "shim" on one side to nudge it up to level.

This is actually an interesting application of standard high school trigonometry. If a thrust vector is pointing straight up to sky, well and good. This is what the flight controller is banking on for its power distribution calculations. But if a motor is tipped to one side by even two or three degrees (barely perceptible to the eye), the aircraft will experience a mysterious lateral force equal to the thrust times the sine of the angle. If the motor is generating a healthy 500 grams of thrust (a little over a pound), three degrees of tilt creates 26 grams of sideways thrust (500sin3°). Small but significant—and the flight controller is not accounting for it.

Maddening: yes. Fixable: absolutely. The motors will be checked and adjusted, and Thiccarus will be bandaged up and flown again. It is also very likely that a Mark II design will surface in the second semester, with higher tolerances for motor angles accounted for from the very beginning and a lighter airframe. Less airframe weight means longer flight times, a more responsive drone, and a greater possible payload.

Providence Engineering Academy: carry on!

(Our final update for this story on the 19th of November. Spoiler alert: it's a happy ending!)

As promised, the motors were checked and adjusted. Ben and Mr. Meadth stayed after school and carefully placed pieces of card under this or that side of the motors to shim them up, bringing them as close as possible to vertical. Three motors were in need of adjustment, but none of them were out of line by more than about two or three degrees.

The drone was powered up, with high hopes... but the end result was exactly the same. Thiccarus wanted to flip over to the side and rotate faster and faster, and nothing could persuade him otherwise. Forget flying too close to the sun—Thiccarus couldn't even get off the ground!

And then...

And then...

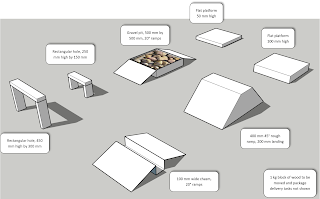

Mr. Meadth had his flash of inspiration, and it all came down to this image:

|

| The source of all problems. |

This diagram shows the initial wiring and setup instructions from the flight controller. A certain teacher thought he had carefully followed the diagram; unfortunately, he had set the actual propeller directions all opposite. For example, propeller 1 was supposed to be rotating clockwise, but it had been set up to be counter-clockwise.

What's the big deal, you ask? Well, while having everything opposite would still be balanced to some degree, the flight controller uses the spinning propellers to control its yaw. Say the craft wants to yaw to the left, it chooses a propeller to spin faster to the right (like propeller 1), and Newton's Law of Reactions takes over. If it wants to yaw to the right, it might choose a left-spinning propeller to do that (like propeller 2). But since each and every one was backwards, the corrective actions it tried to take were in every case making the situation worse. If it started drifting left, it would end up spinning more left—a classic vicious circle if ever there was one.

A quick click of a checkbox in the computer and that was solved. All propellers: backwards. Oops.

|

| Propellers... spinning the correct way! |

|

| You know you're doing something right when you're looking at the bottom of the drone |

|

| This portable outdoor screen receives video input from two onboard cameras |

Today marks another successful series of flights. We currently get about ten minutes of air time with two fully charged batteries. Three students plus teacher have been brave enough to fly around a little bit. No major accidents—perhaps a leg snapping off here or there with a rough landing!

Lessons learned:

- Persistence pays off. If this is a thing that can be done, then you can do it. Just get out there and keep troubleshooting until you work it out.

- This is a new era of high school education. To collaborate on a CAD model, 3D print it, order the electronics, and create a hovering 2.2 kg monstrosity in the space of three months is just not something a school could have done in-house ten years ago. Truly these are amazing times!

- These students are capable. With the right leadership and direction, they know how to think and problem solve and calculate and design. They will go far.

The story ends here, but keep an eye out for Mark II! We just can't resist. There are already so many things that could be optimized (chiefly, stronger airframe and lighter weight). Lighter weight means more air time, so bring it on! Look out for Son of Thiccarus in the second semester, and until then, stay posted.