(Our latest blog article comes courtesy of Joshua in the 10th Grade. Thanks, Josh!)

|

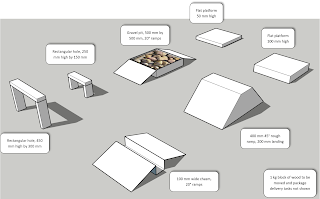

| The original CAD model of the obstacle course, constructed over several weeks by our indefatigable teaching assistants, seniors Josh and Claire |

The testing included nine phases (any of which could be skipped) all while carrying a payload. The teams would go through two gates of different sizes, over a gravel pit, up onto platforms of varying heights of 50 and 100 mm, push a block with the mass of one kilogram, go across a chasm, and make their way up a 45° incline. At the end of the run, the robot would be required to drop off the payload. The driver for each team would first do this routine while watching from nearby, and then once again using only a first-person camera view.

|

| Davis gets his team's robot up onto the 50 mm platform with no worries at all |

The first robot to test was the "Trapezoidal Tank”. This robot was built by Nolan, Davis, and Alan. They felt ready for the first trial of the course, but decided to skip the 45° incline. Everything ran smoothly until the payload drop at the very end. They realized something was wrong.

The payload mechanism’s motor came unplugged!

Davis, the driver, thought up an idea. The payload was resting on top of the robot. What if he just flipped the whole robot over? Using the tank’s "tail", he flipped the robot up onto its end and delivered the payload.

|

| Although not able to climb the full 45 degree slope, with a slight modification the Trapezoidal Tank was make it at 40 degrees |

|

| A moment of pure glory! Davis upends the entire robot and performs the obligatory victory dance! |

On the camera-only run, the course was successfully completed again with only one obstacle skipped.

|

| Caleb taking things in his stride, as the long-legged robot effortlessly clambers over the gravel pit obstacle |

|

| Caleb attempts to steer by camera only-- no easy feat! |

|

| Pushing the one-kilogram block away, the package waiting to be delivered is clearly seen on the right-hand side of the robot |

|

| This complex (and squeaky) maneuver involves a series of high-torque gymnastic activities |

|

| Anaconda brings its bulk to bear on a one-kilogram block of wood |

|

| This monster robot leaps 100 mm platforms with a single bound! |

|

| James steers the Iron Horse through both gates and up onto the 100 mm platform |

Finally, the "Iron Horse” entered. This robot was built by Sam K., James, Joshua, and Kaitlyn. The design was simple yet effective. However, the extra mechanism they had added to their robot at the last minute broke! It was designed to help them get up onto the two platforms. Fortunately, there was enough power available for it to slowly assist with the obstacle it was built for.

|

| Charging over the gravel pit with a huge ground clearance |

Shortly after, that extra mechanism fell off and so did the payload. In a lengthy and complicated series of maneuvers, James used the one-kilogram block to push the payload over into the designated area.

|

| End of the road: the Iron Horse capsizes while trying to free its jammed package (the small yellow catch was supposed to release and allow the hinged door to fall) |

On the camera-only run, the Iron Horse's payload wouldn’t release. James used the gravel pit to try to get the payload to come loose, but the robot flipped over. He attempted to flip the robot back over, but it tipped over on its side instead. This run was incomplete.

The lesson to be learned for these four groups? Each problem can be solved in many different ways, but some are more effective than others. In every problem you encounter, consider those many solutions and then choose the most effective one.